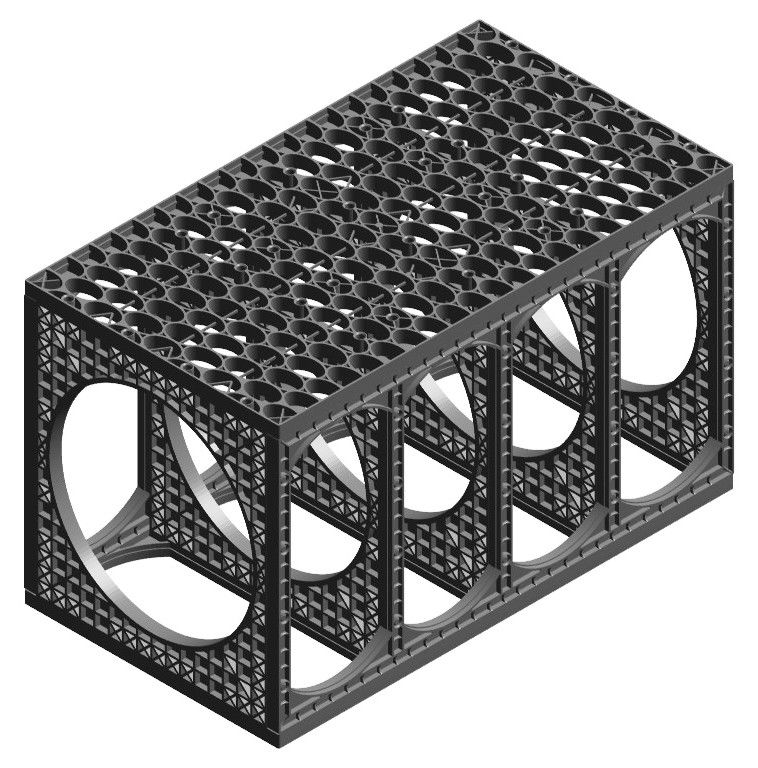

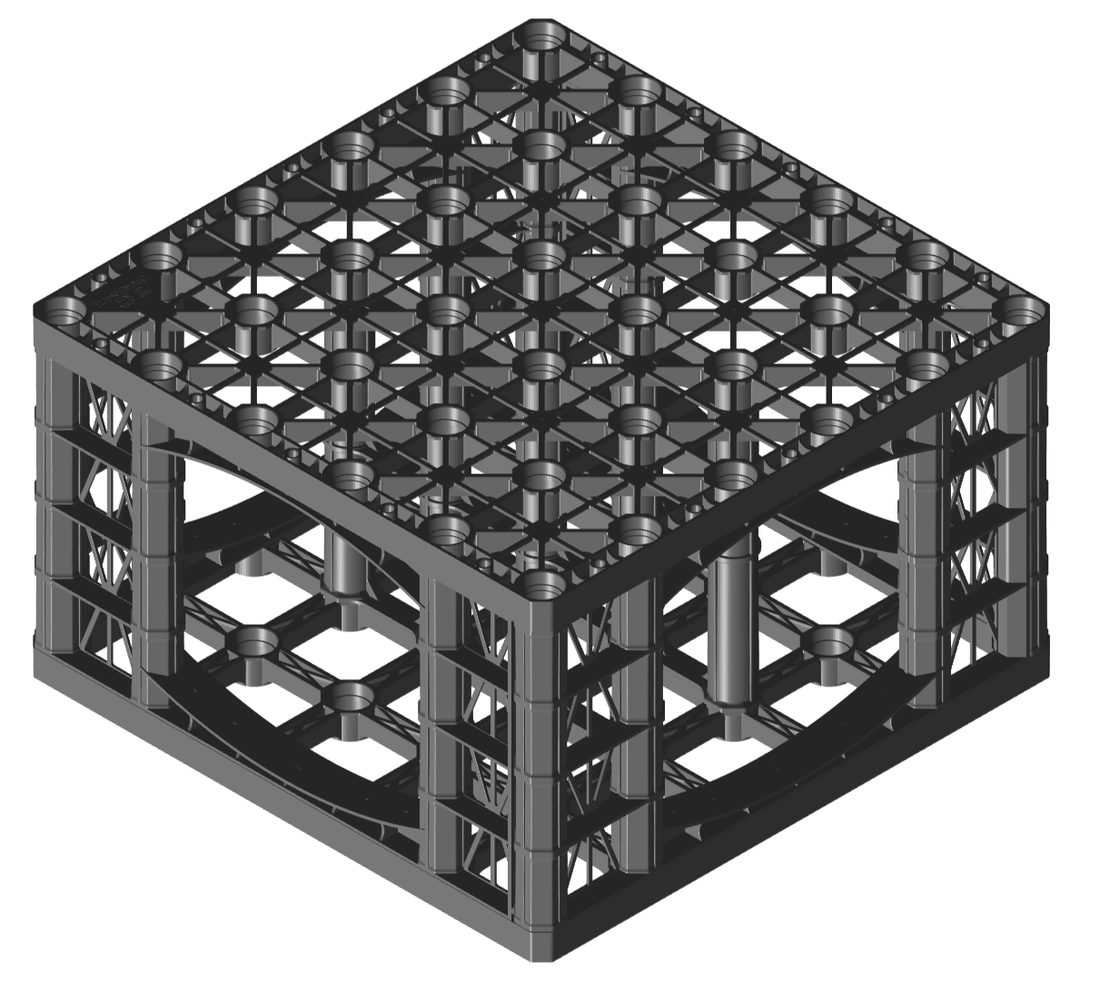

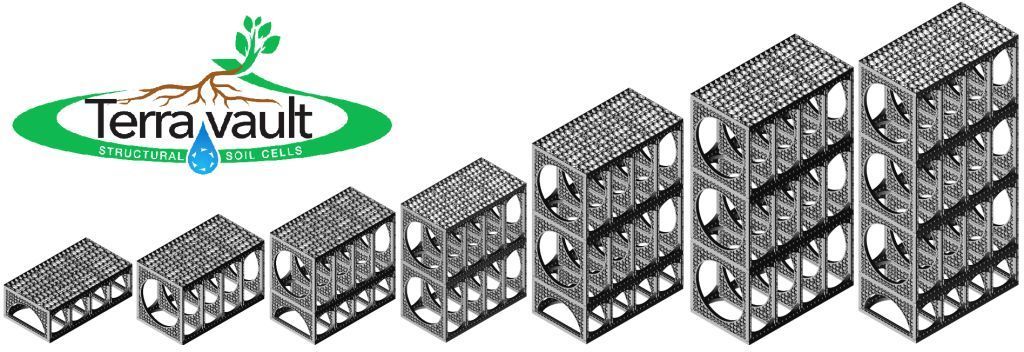

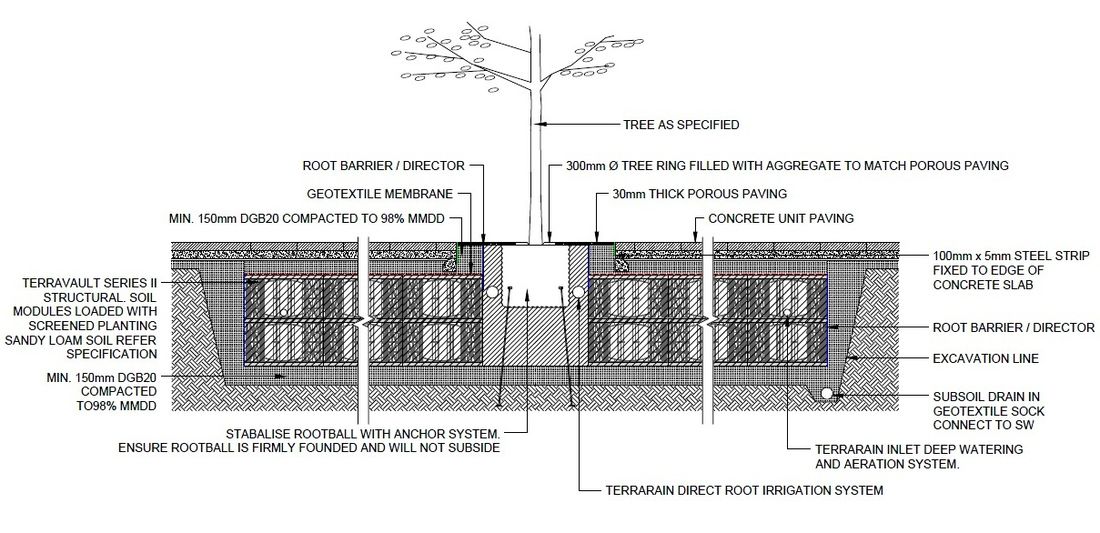

| TerraVault I & II Modules are modular units that assemble to form a skeletal matrix that supports relevant pavement loads while providing large volumes of un-compacted soil within the structure for free root growth. The open, skeletal matrix provides a maximum growth zone for tree roots. More than 95% of the Internal Void volume is available for un-compacted soil and root growth. Traditionally rock and soil mix use to provide support for pavement, while permitting some root growth within the pavement. TerraVault I & II System have moved this principle forwarded by entirely replacing the rock (80% of the total volume), the engineered modules provide the structural strength for pavement loads whilst providing free un-compacted soil for root zone to grown and trees to flurish in an urban environment. | System Benefits: - Heavy Load bearing capacity.

TerraVault Modules have a high load bearing capacity of up to 65 t/sqm. UNCONFINED - Uniform Load bearing Capacity

Each unit is self-supported and is a load bearing structure, unlike other products which use spacers. - Modular Structure provides Design Flexibility

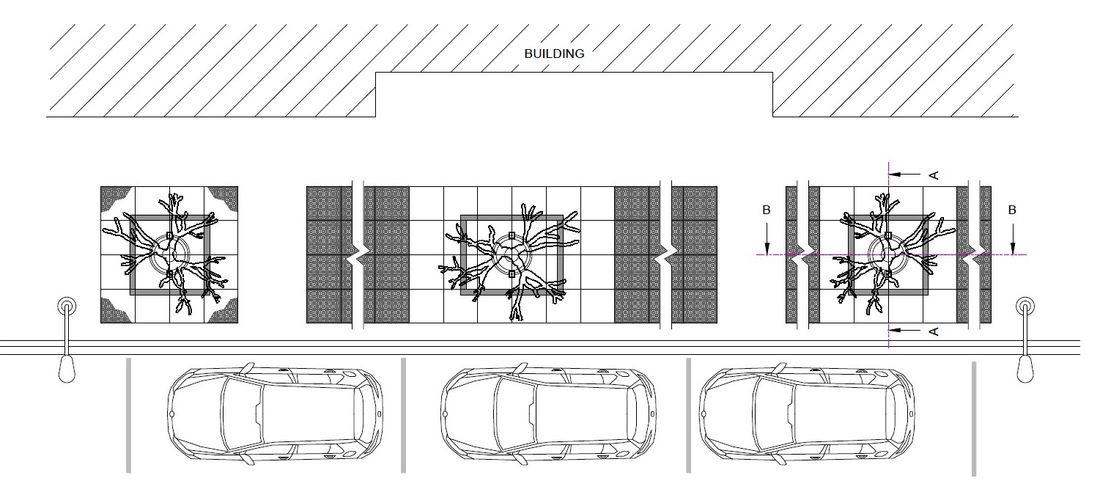

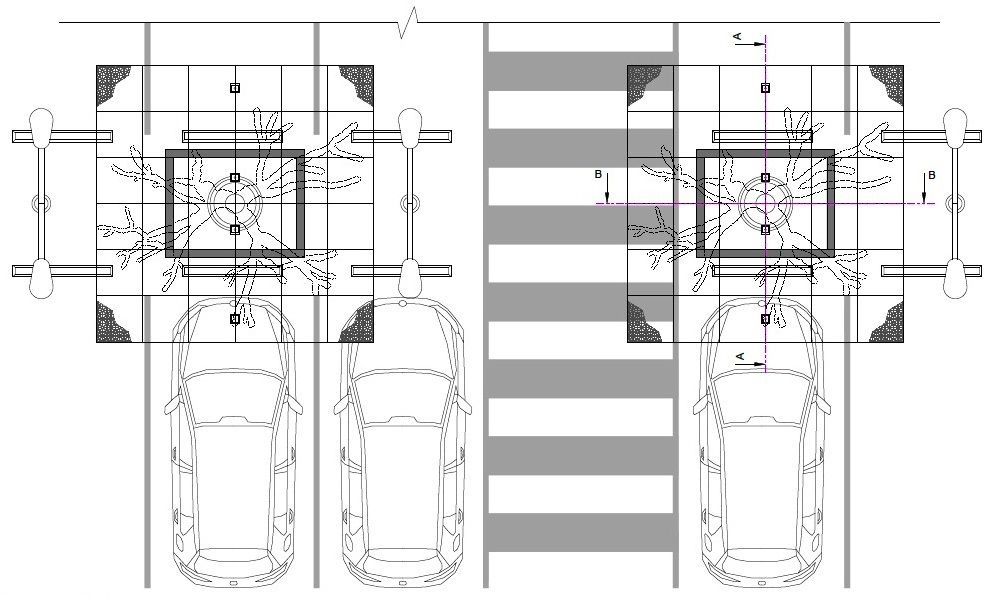

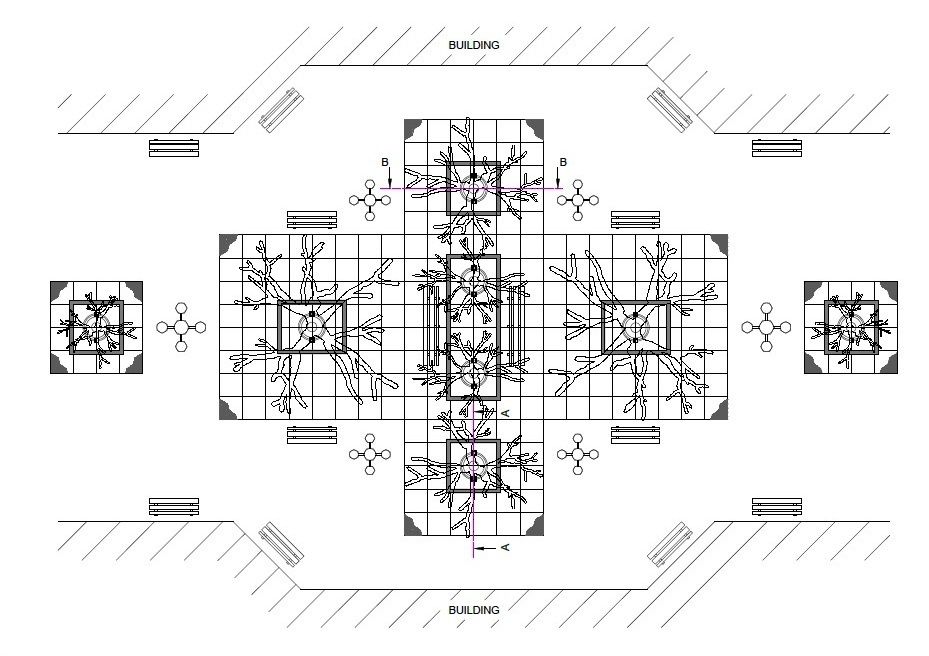

Modular Nature of the system helps designers to create any shape, any size and fits tight spot. - Use Strength with Flexibility.

Reduce or Increase the number of internal support plates to use achieves Required load rating whilst keep costs low. - High Internal Void Ratio.

TerraVault Modules have 95% internal void Ratio, meaning more space for un-compacted soil and roots and water management. Allowing heathy root and plant growth. Up to 95% surface void ratio providing free un-obstructed root growth and movement in the un-compacted soils. - Quick & Lightweight Easy to install.

TerraVault Modules are light weight and easy to install by unskilled labor, without the need of any heavy Machinery Supplied in kit form its easy delivery and handling and reduces transport costs. - Easy to Infill and Top Up.

Unlike other systems, this is a single component module which is easy to infill and lock in place. Reduces installation time and costs. - Environmentally Friendly.

Made from Recycled Polypropylene the Terra Vault Modules are Green label Certified. - High Lateral load Capacity

The TerraVault Modules have a high lateral load carrying capacity of > 7.5 t/sqm. Internal plate layout ensures uniform load distribution and load capacity. Lateral forces must also be considered for engineering design of tree pits, when in proximity of traffic areas. TerraVault units lock together vertically and laterally if required to form a single structure with excellent modular strength, both vertically and laterally. - Enhances and Recycles Stormwater.

There are many WSUD methodologies to capture and utilize valuable rainfall using the TerraVault system and other Rainsmart product range to enhance growth of trees in an Urban Environment. Applications: |